Straight pipe threads can be form tapped using only a high quality drilled hole.Straight hole procedure will reduce tapping torque and improve tool life. 10-24 Tap Material HSS-E Thread Length 3/8 in Overall Length 2-3/4 in 75 Thread Drill Size 4. The benefits of burnished, high quality threads at the top of the hole provide excellent sealing capability for the part. These benefits include improved thread finish. The bottom of the hole may have partially formed crests with open “RABBIT EARS”. Jarflo roll form pipe taps (NPT & NPS) have significant advantages over cutting taps in many applications. The straight hole method will result in a full, sharp-crested threads at the top of the hole.

The Jarflo tap will ultimately produce the proper tapered thread by forming the material from the top to the bottom of the hole. Straight Hole – many applications for tapered pipe threads may use a straight hole.Tapered holes require the most torque and HP for tapping. Tapered hole may be drilled, reamed or cored.

1024 thread forming taps series#

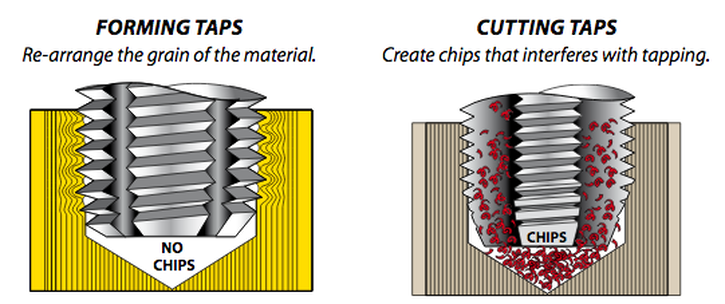

It is not practical to thread form NPTF & NPSF threads because 100% thread is required, and the crests need to be fully formed. The OSG Thread Forming Tap: 10-24, UNC, Modified Bottoming, Cobalt, Bright Finish H7, Series HY-PRO NRT can be found within the Thread Forming Taps category. These benefits include improved thread finish, stronger threads, longer tap life, faster tapping speeds and no chips. * Values are calculated for Length of engagement of 5xPitch.Jarflo roll form pipe taps (NPT & NPS) have significant advantages over cutting taps in many applications. When it comes to 10-24 General Purpose Chip-Free Thread-Forming Taps, you can count on Grainger. As a starting point, however, 55 for maximum drill size and 75 for minimum drill size can be used as a guide. Manufactured from powdered metal high-speed steel coated for thread cutting in various. There is no true method of predicting percent of thread that will be obtained when tapping with forming taps due to the many variables involved. * Permisable values for thread Class 3A # Description Value (Inch) Value (mm) es Allowance 0 (Ref) 0 (Ref) d Major Diameter 0.1828 - 0.19 4.643 - 4.826 d 2 Pitch Diameter 0.1604 - 0.1629 4.074 - 4.138 d 3 Minor Diameter Swageform thread forming screws allow you to eliminate the tapping process as the screw will form your threads during installation-if you are tapping holes. Left-hand spiral flutes to push chips ahead in through holes. Form taps are ideally suited for both blind & through holes. Because no chip is produced, breakage due to chip packing and bird nesting is eliminated. For calculations of different engagement length use the Thread Calculator Home products Threading Forming Forming Forming Taps Forming taps, unlike cut taps that remove metal, work by compressing the work material to generate the desired thread. * Values are calculated for Length of engagement of 5xPitch.

0 kommentar(er)

0 kommentar(er)